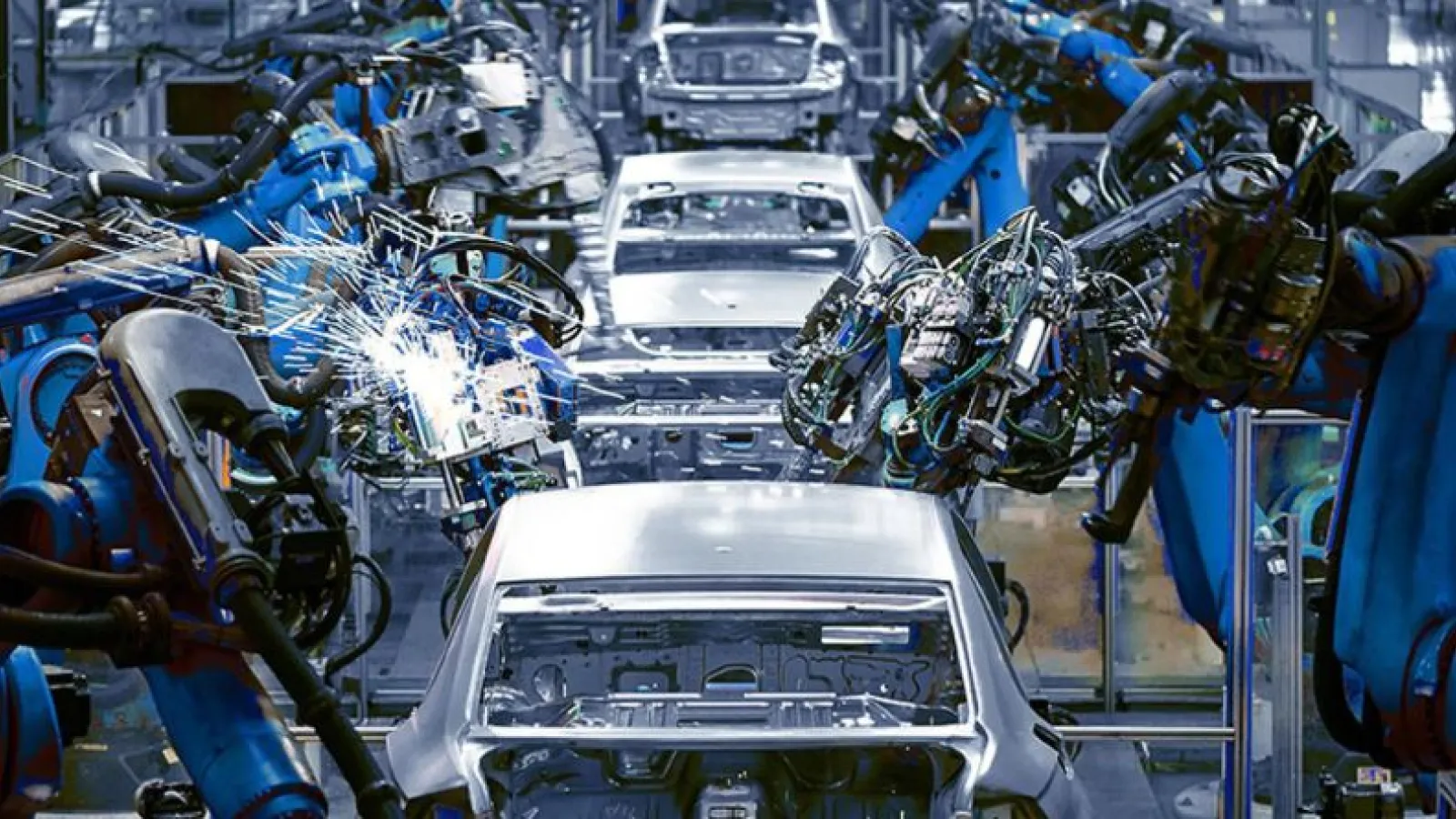

Smart Tracking Solutions for Manufacturing

Real-time visibility of assets, inventory and work-in-progress to keep your factory running efficiently from production to warehousing and distribution

Key Benefits

Optimise your manufacturing business with tracking technologies

Are you meeting your production goals?

Our integrated tracking systems help manufacturing businesses stay competitive by delivering real-time visibility of assets, inventory and work-in-progress across the entire production cycle. From raw materials and critical tools to finished goods and returnable transport items, RFiD Discovery gives you a clear picture of what you have, where it is and how it’s being used.

By combining RFID, BLE, UWB, LoRA, GPS and other leading tracking technologies, we support lean manufacturing practices, reduce unplanned downtime and eliminate delays caused by missing parts or equipment. Accurate data on the movement and utilization of assets helps you optimize production lines, reduce bottlenecks, protect margins and make better-informed investment decisions.

Whether you need more visibility of work-in-progress on the shop floor, tighter control of stock in your warehouse, or tracking of staff uniforms and other reusable items, our flexible solutions can be tailored to your processes, sites and systems.

This system is the best technology for industry 4.0, enabling real time asset tracking, accurate location and workflow digitalisation.

Heading

Case Study: Manufacturing company Aubert & Duval revolutionizes operations and efficiency with LiftTrak

Read more

Improving supply chain management

Our solutions are helping many business improve production output by streamlining supply chain processes. This includes production flexibility, consistent delivery and order fulfilment, warranty and returns processing as well as inventory and asset management. Tracking your assets and inventory can provide:

- Kanban processes for fast replenishment

- Truckload audits to match ERP/WMS with actual shipment

- Location visibility of assets, products or parts in the supply chain

- Accurate inventory levels in warehouses and yards

Heading

Case Study: Clothing company Brook Taverner transforms goods-in processes with RFID portal

Read more

Work in progress (WIP) tracking

In the manufacturing industry ‘work-in-progress’ tracking is vital to ensure production processes can happen efficiently and without delay.

Our WIP tracking solutions provide management and operational teams with real-time information on production processes to deliver:

- Enhanced product quality through product tracking

- Increased efficiency

- Valuable data to improve strategic business decisions

- Reduced need for excess stock with better inventory management

Worker automation and task management

To improve productivity, companies need to increase staff efficiency. Our software platform can help empower your workers with real-time information and tools to be more efficient.

This can include Kanban processes for fast replenishment and smart stock holding, forklift route optimization in warehouses or on the production floor as well as employee task tracking and KPI reporting.

Frequently asked questions (FAQs) about tracking in manufacturing

What are the most common use cases of RFID and RTLS in manufacturing?

RFID and Real-Time Location Systems (RTLS) are used in manufacturing to track work-in-progress (WIP), ensure tools and fixtures are always available, monitor inventory movement, and locate returnable transport items (RTIs) across the production cycle. They reduce downtime caused by missing assets, automate process verification, and improve production flow by showing where every item is in real time.

How does real-time tracking improve production efficiency?

Real-time tracking provides instant visibility of parts, assets, and equipment across the shop floor, allowing teams to remove bottlenecks quickly. It reduces search time for tools and components, prevents production delays due to misplaced items, and provides accurate data for lean and just-in-time (JIT) processes. Many manufacturers see reduced lead times, fewer errors, and smoother production planning as a result.

What ROI can manufacturers expect from using RFID or RTLS?

ROI typically comes from reduced labor time, fewer lost or misplaced assets, optimized inventory levels, and lower production downtime. Manufacturers often recover their investment in 12–24 months, with common gains including a 20 - 40% reduction in search time, fewer mis-shipments, and tighter stock control that prevents over-ordering.

What technologies are best for tracking assets in a manufacturing environment?

Different technologies excel in different scenarios, for example:

- RFID – ideal for inventory tracking, WIP, tools, and component flow

- UWB (Ultra-Wideband) – best for high-accuracy, real-time indoor location within a few centimeters

- GPS / LoRa – suited to outdoor or yard tracking over long distances

A hybrid approach often provides the most complete visibility across the entire production process.

Can the tracking system integrate with MES, ERP or WMS platforms?

Yes. RFiD Discovery platforms can integrate with major MES, ERP and warehouse management systems to synchronize asset movements, update production stages automatically, and feed location data into business dashboards. This ensures accurate reporting and eliminates manual data entry.

Our manufacturing tracking solutions include:

Warehouse real-time inventory tracking

Worker productivity tracking

Tracking returnable transport items (RTIs)

Yard and outdoor storage management

Asset tracking