Work in progress (WIP) tracking

Benefits

Why work-in-progress tracking matters

In sectors such as manufacturing, warehousing and logistics, healthcare, construction, oil and gas, mining, aviation or retail, limited visibility into work-in-progress makes it difficult to control workflows, maintain quality and meet delivery commitments. Without accurate, real-time insight, delays, bottlenecks and errors often go unnoticed until they impact performance. Work-in-progress (WIP) tracking addresses these challenges by providing continuous visibility across operational stages, enabling organisations to optimise processes, reduce risk and make faster, data-driven decisions.

The challenges of managing work-in-progress without real-time tracking

Across industries, limited visibility into work-in-progress can quickly impact performance, quality and delivery timelines.

Limited visibility across processes

Manual tracking methods and disconnected systems make it difficult to understand where items, materials or assets are at any given moment, particularly in fast-moving or multi-site operations.

Bottlenecks and delays

Without real-time data, bottlenecks often remain hidden until they disrupt schedules, resource allocation or customer commitments.

Errors and quality issues

When items are not automatically identified and verified at each stage, process deviations, assembly errors or compliance risks become more likely.

Inefficient use of resources

Teams spend valuable time searching for items, reconciling data or correcting errors instead of focusing on high-value operational tasks.

Heading

A global rail leader improved work-in-progress visibility, production control and operational efficiency using RFID tracking solutions.

Read the full case study

How RFiD Discovery supports WIP tracking

End-to-end visibility across production flows

RFiD Discovery supports work-in-progress tracking by providing end-to-end traceability of WIP, machinery, tools and parts using RFID and intelligent identification technologies. Real-time data delivers clear visibility into production status, item identity and location across workshops and operational sites, helping organisations maintain control over complex workflows.

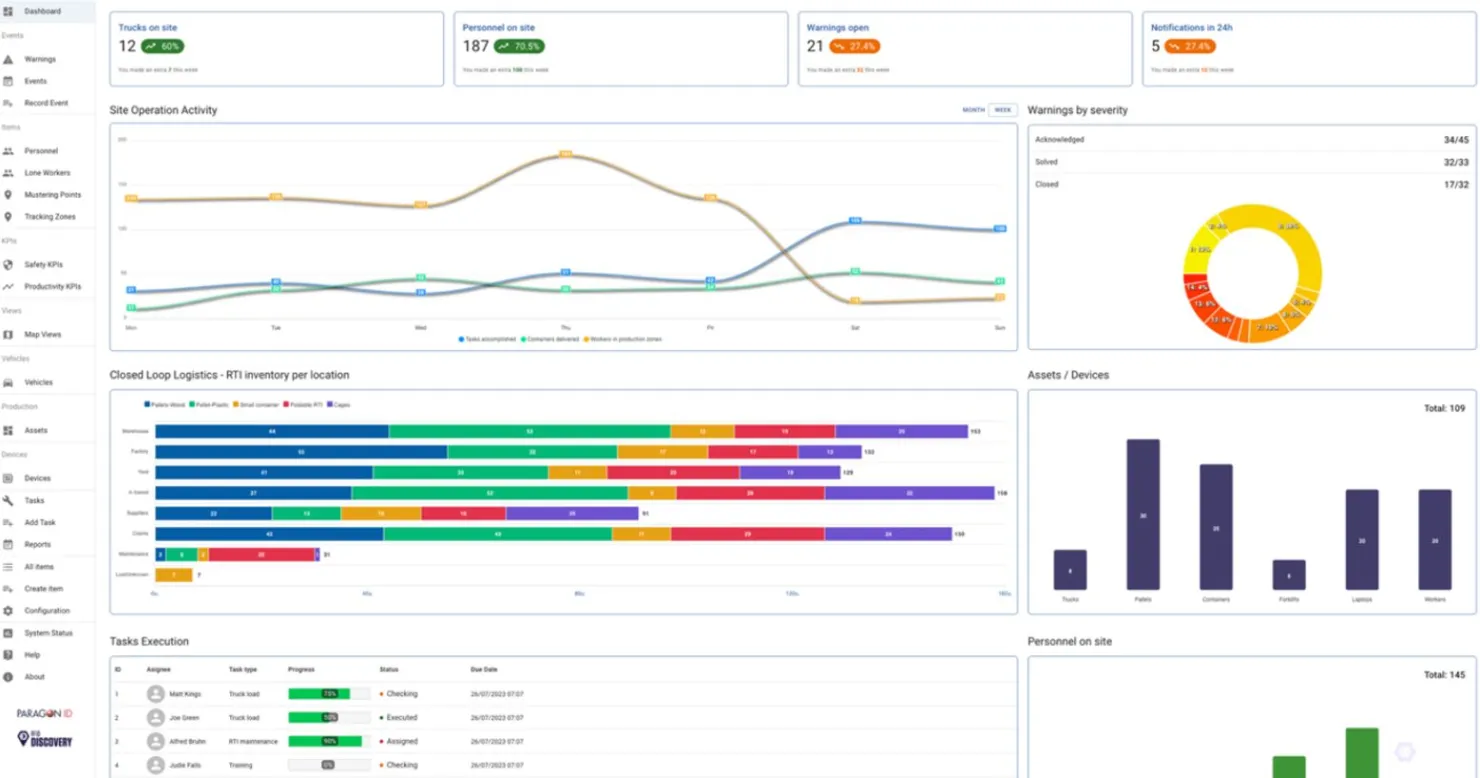

Standard KPI dashboard

Flow control, traceability and system integration

By enabling line flow control, FIFO compliance and effective rework management, the solution improves production efficiency and coordination. Tracking of assembly parts, raw materials and intra-logistics movements, combined with seamless integration with ERP and MES systems, ensures accurate lifecycle visibility and automated process execution.

Frequently asked questions (FAQ)

What is work-in-progress (WIP) tracking?

WIP tracking is the automated monitoring of work-in-progress items throughout the production cycle, giving manufacturers real-time insights into item location, status and flow.

Why use RFID for WIP tracking?

RFID enables automatic, non-line-of-sight identification, making it well suited to environments where speed, accuracy and reliability are critical.

Which sectors benefit from WIP tracking?

WIP tracking is valuable across sectors such as manufacturing, warehousing and logistics, healthcare, construction, oil and gas, mining, aviation and retail, particularly where workflows are complex and visibility is essential.

Can WIP tracking integrate with existing systems?

Yes. RFID-based WIP tracking integrates with ERP and other operational systems to improve planning, reporting and process automation.