RFID portals

Benefits

It used to take us three hours to carry out manual spot checks on a typical shipment of up to 25,000 garments, inherently introducing potential errors. Now [with the RFiD Discovery conveyor portal] we can efficiently validate whether all expected items are present in less than one hour, savings us both time and money.

What RFID portals do

An RFID portal creates a read zone that detects multiple passive RFID tags at once. It records item movement automatically at key transition points, even when items are stacked, boxed, or moving quickly. Portals can run as stand-alone, software-agnostic units for system integrators, or as part of a full TrackSphere™ location and inventory solution.

RFiD Discovery offers passive UHF RFID portals for key flow points in logistics and manufacturing. The range covers conveyor tunnels for boxed items, outdoor gate portals for vehicles, and dock-door portals for pallet and roll-cage movements. Each portal delivers high read accuracy, direction sensing, and simple integration.

Why use RFiD Discovery RFID portals?

Real-time stock and asset visibility

RFID portals capture every movement event at the moment it happens. Warehouses and factories gain a live view of what has arrived, what has left, and where stock is flowing.

Faster goods-in and goods-out

A single pass through the portal can read hundreds or thousands of tagged items in seconds. This removes scanning bottlenecks at busy dock doors, gates, and conveyors.

Higher accuracy with fewer manual errors

Automation reduces missed scans, double counting, and paperwork mistakes. Operators spend less time searching for items or correcting stock records.

Lower operating cost

By reducing labour time per transaction and preventing inventory losses, portals deliver a rapid ROI in high-volume supply chain operations.

Easy integration, flexible deployment

The portal range is designed in-house and supplied as software-agnostic hardware. It integrates with WMS, ERP or MES platforms through existing middleware, or connects directly to TrackSphere™.

Heading

Brook Taverner transformed high-volume goods-in by checking over 22,000 items in one hour using RFiD Discovery’s conveyor RFID portal.

Read the full case study

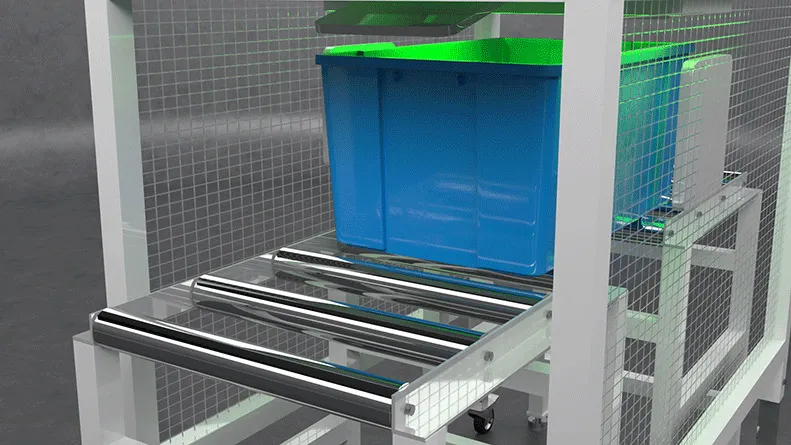

Conveyor RFID Portal

A powered tunnel portal for automated UHF RFID scanning on conveyors. It reads multiple tags in one pass, records in/out direction via infrared sensing, and flags incorrect items. A weigh cell can add shipping verification. It supports high-volume goods-in, as shown at Brook Taverner.

- Throughput: 1,500-25,000 items/hour

- Box size: built to requirement

- Format: fixed or mobile.

- Ideal for: goods in/out, inventory verification, returns, e-commerce automation.

Outdoor supply chain RFID portal

A rugged IP67 portal for reading tagged goods and assets on passing vehicles. It detects direction of travel and uses LEDs to alert on exceptions. It suits articulated curtain-sided vehicles.

- Read gap: up to 10 m.

- Speed: 500 reads/sec stationary, 300 reads/sec at 5 m/s.

Ideal for: distribution centres, yard gates, outdoor shipping/receiving, RTI control, manufacturing WIP.

Indoor Slimline Supply Chain RFID Portal

A portal optimised for dock doors and bay entrances. It creates a controlled read zone to capture all tagged items entering or leaving, with real-time LED exception alerts.

- Designed for: pallets, roll cages, cartons, and high-volume door traffic.

- Ideal for: dock-door receiving and dispatch, cross-dock checks, returns and re-stock confirmation.