TrackSphere™: Industrial tracking software for people, assets and inventory

Benefits

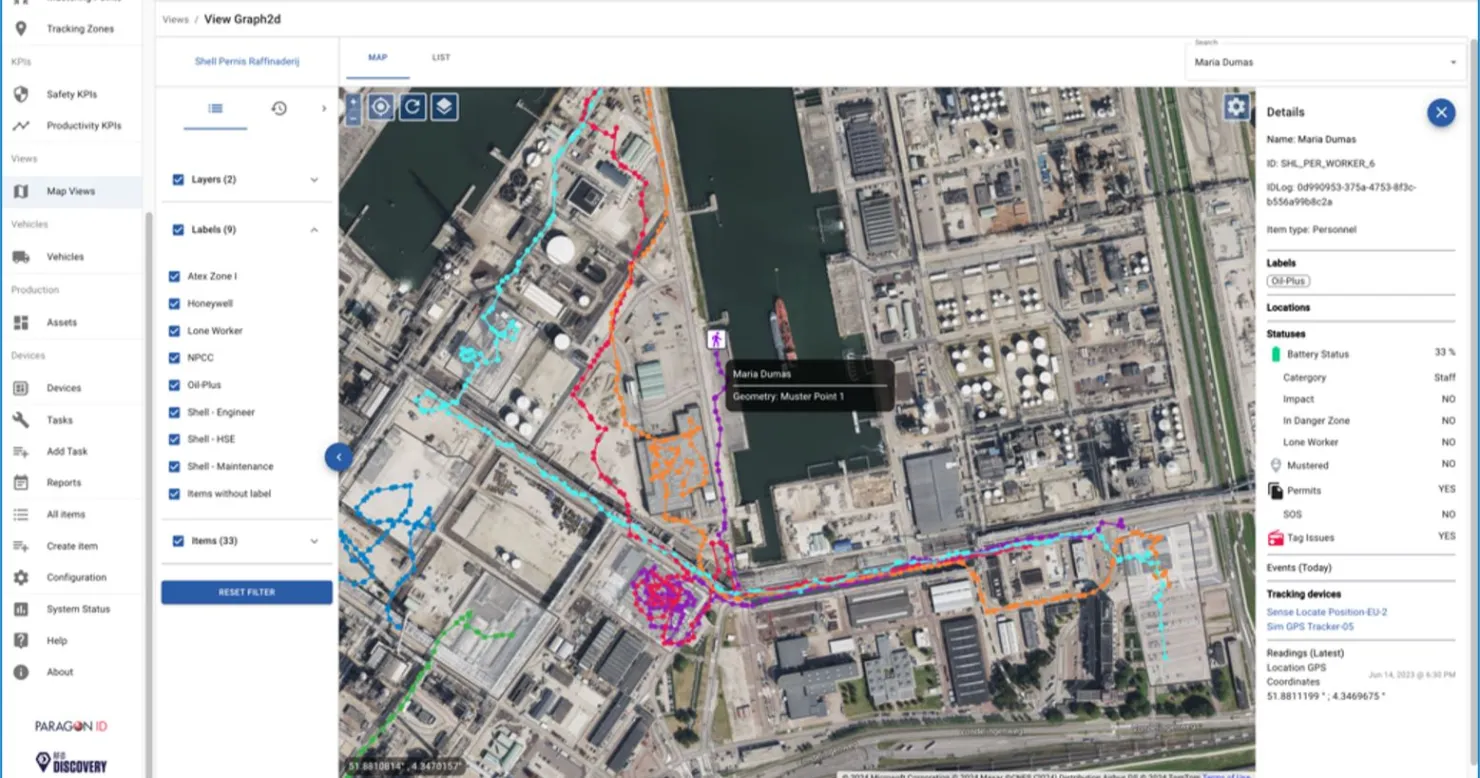

Real-time tracking and visibility across industrial environments

TrackSphere is RFiD Discovery's industrial tracking software that delivers real-time visibility of people, assets and inventory across complex industrial environments. Designed for industrial sectors including manufacturing, logistics, construction, oil and gas and mining, it supports accurate monitoring, reduced inefficiencies and stronger operational control across daily activities.

By combining precise location data with process monitoring and automation, TrackSphere turns tracking data into actionable insights that support safer, smarter and more efficient operations.

Why choose TrackSphere for industrial tracking

Designed for complex industrial environments

Built to operate reliably indoors and outdoors, even in demanding and large-scale industrial conditions.

Easy to configure and manage

No-code configuration enables teams to adapt tracking rules, alerts and dashboards without technical expertise or ongoing development.

Actionable insights for continuous improvement

TrackSphere transforms tracking data into meaningful insights that help organisations improve efficiency, reliability and operational performance over time.

Heading

How TrackSphere helped an oil and gas construction company improve workforce visibility with smart geofencing

Read the full case study

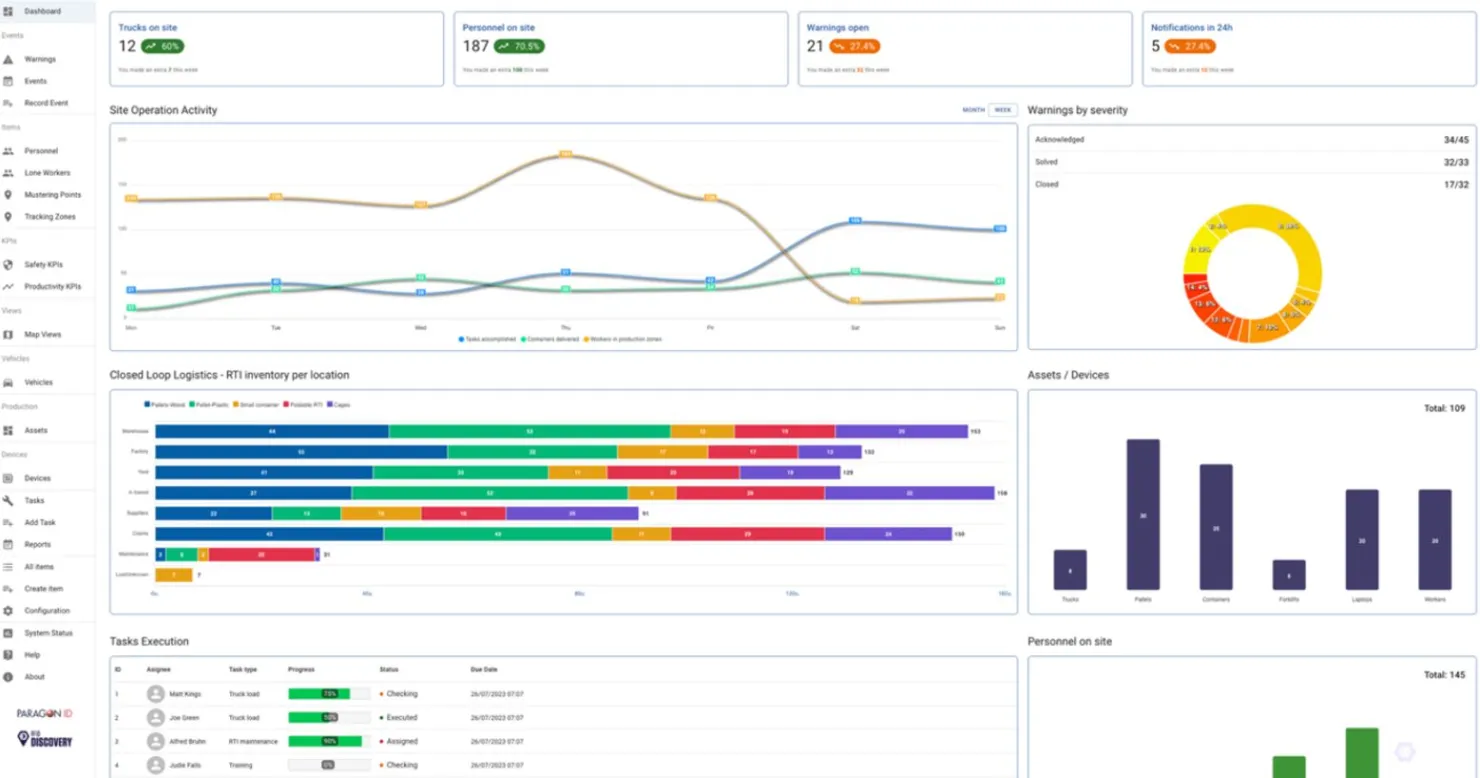

Improve visibility and control across industrial operations

TrackSphere enables organisations to monitor movements, tasks and workflows in real time. By centralising tracking data in a single interface, it provides a clear overview of operational activity and resource utilisation.

This improved visibility helps teams:

- Reduce time spent searching for people, equipment or materials

- Minimise asset loss and operational delays

- Improve coordination between departments and teams

- Respond quickly to operational or safety events

The result is increased efficiency, reduced downtime and stronger operational control.

Operational KPI dashboard with real-time tracking insights

Real-time map view of people, assets and inventory

Flexible, scalable and technology-agnostic tracking software

TrackSphere supports multiple tracking technologies, enabling organisations to select the most appropriate solution for their environment and accuracy requirements:

- RFID (Radio Frequency Identification)

- UWB (Ultra-Wideband)

- BLE (Bluetooth Low Energy)

- GPS, Wi-Fi and LoRa

The software can be deployed on-premise or in the cloud and integrates seamlessly with enterprise systems such as ERP, WMS and MES. This flexibility ensures TrackSphere fits easily into existing industrial infrastructures and scales across single or multi-site operations.

Industrial tracking use cases across key sectors

Warehousing and logistics

Manufacturing

Construction, oil & gas and mining

Heading

TrackSphere case study: real-time production tracking boosts control and efficiency for a global rail leader

Read the full case study

Frequently asked questions (FAQ)

What is industrial tracking software?

Industrial tracking software provides real-time visibility of people, assets and inventory within industrial environments, helping organisations improve efficiency, coordination and operational control.

What can be tracked with TrackSphere?

TrackSphere can track people, equipment, tools, vehicles, materials and inventory, depending on operational needs and site configuration.

Does TrackSphere support indoor and outdoor tracking?

Yes. TrackSphere supports both indoor and outdoor environments using technologies such as RFID, UWB, BLE and GPS, depending on coverage and accuracy requirements.

Can TrackSphere integrate with existing systems?

Yes. TrackSphere integrates with enterprise systems such as ERP, WMS and MES, allowing tracking data to support broader business and operational processes.

Is TrackSphere suitable for multi-site operations?

TrackSphere is designed to scale across single or multiple sites, making it suitable for organisations with distributed or global industrial operations.